Smart adhesive handling systems

Innovative application heads for assembly preparation

The areas of application are diverse and are used primarily in the automotive and electronics manufacturing sectors as well as in plastics technology. Precise application of adhesive tapes is indispensable, especially when preparing plastic components for assembly, such as trim strips, bumpers or trim panels.

Application heads (TapeHeads) of Glaub are devices with which adesive tape can be applied automatically. Depending on the appliaction, the application process can theke place in a straight line, as curves, inclines or valleys.

- Equipment for application processes

- In industrial design for continuous workflows

- The design is robust and maintenance-free, with standardized repeat parts

- The anti-stick coating on the contact parts guarantees high process reliability

- The system weights are designed for use on lightweight robots (LBR cobots)

- The practical changeover concept ensures automatic applicator head changeover

We do not have the one applicator…

… but a whole range of product-specific applicator heads.

With years of practical experience and know-how, Glaub develops flexible applicator heads for different adhesive applications and tapes – tailored to the specific requirements of its customers

With highly dynamic traversing movements, application heads from Glaub guarantee optimum production results.

-

Manually guided unit

-

Use with robot (LWR/IRB)

-

Use on a servo axis/portal

Technical feasibility

The adhesive and sealing tapes available on the market have very different compositions and properties.

Therefore, an upstream feasibility study (FST) ist required to technically validate the processability of the adhesive and sealant tape.

Based on these investigations, well-founded decisions can be made regarding the feasibility of your project.

Without these preliminary investigations, no reliable statement can be made regarding process reliability. The customer bears the technical risk

The feasibility studies refers to:

- Guiding behavior and interactions with the TapeHead

- Cutting ability/cutting behavior of the adhesive/sealant tape supplied by the customer

You have questions about feasibility or a specific project for which you need support?

TapeHead

-

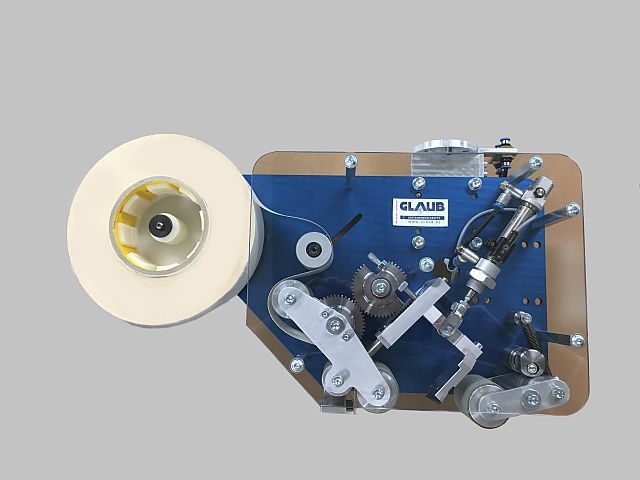

TapeHead-1000

Suitability: for thick double-sided tape with liner

- For standard tape widths of 6-25 mm

- Automatic applicator head for foam tapes

- Effector for manual or robot-guided application processes

- Integrated cutting unit for cutting tapes to lenght

- Exposed application roller for narrow webs etc.

- Suitable for tape rolls or cross spools

-

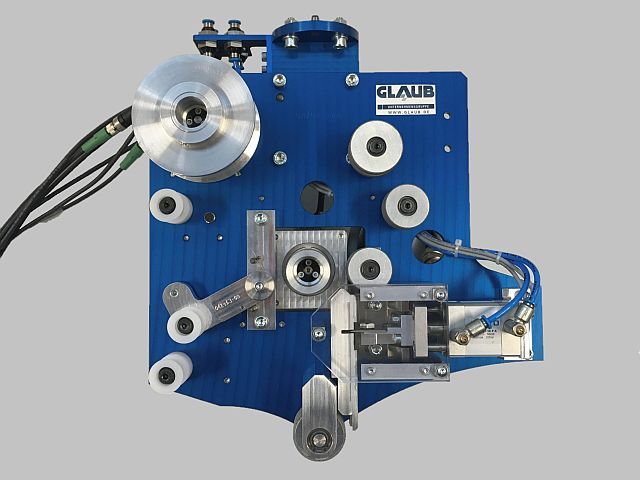

TapeHead-2000

Suitability: for thin adhesive tapes (single-sided or double-sides with liner)

- Automatic applicator head for masking tapes and thin film tapes

- For standard tape widths up to 50 mm (strip widths up to 250 mm on request)

-

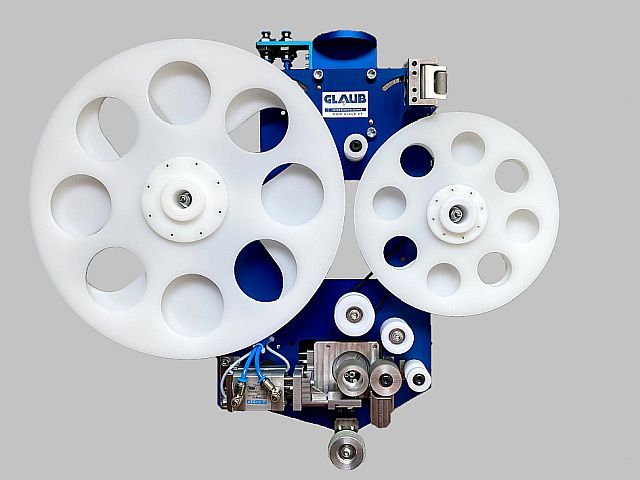

TapeHead-3000

Suitability: for double-sided adhesive tapes with liner rewinder

- For standard tape widths of 6-25 mm (other tape widths on request)

- External material supply via large spool possible

- Integrated liner rewind for ideal assembly processes

-

TapeHead-4000

Suitability: for single-sided adhesive tape with liner including integrated rewinder

- For standard widths from 6-50 mm (other tape widths on request)

- Automatic applicator head for adhesive tapes

- for sealing

- for noise reduciton

- for permanent surface protection

PrimPen

-

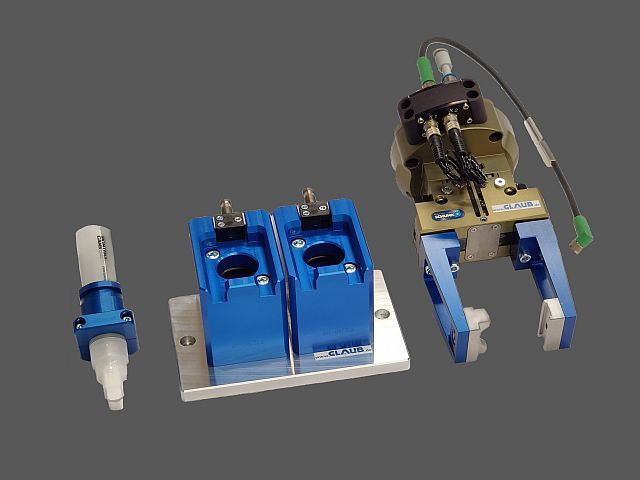

PrimPen-1000 | Changing system for primer preparation

Set consisting of: Primer Pen Holder, Clamp Holder with Quiver (2-fold) and Primer Pen Gripper

… is essential in chemical surface pre-treatment. With our primer pen changing system, we have created a cost-effective and simple automation solution that is ideal for use in one/two-shift production operations.

Wherever physical surface activation cannot or should not be used, you can prepare the primer quickly and easily with this automatic solution.

The result is a chemical reinforcement of the adhesion and thus also a better adhesive effect between the adhesive medium and the substrate.

- Easy integration into the automated application process of self-adhesive media such as; adhesive tapes, assembly and bonding foam tapes.

- Accommodates marker pens that can be filled with 20 ml of liquid.

- Various viscous media can be applied via the marker’s pump system (degreasing before adhesive processes, etc.).

- Quiver with seal to the inserted pen to prevent drying out.

- Multiple units of pen and quiver can be cobined, e.g. to use different media or to achieve long autonomy times.

- Precise, clean application with reliable repeatability guaranteed.

- Relief of employees from monotonous work.

- At the same time, reduction of exposure to hazardous substances or solvents in the direct work environment.

- The result = twofold health promotion for the employees.

Free information

for you!

You want to know more about the different functionalities of our application heads? You can request the desired data sheet via our contact form.

Do you already have a concrete project on the subject of applying? Please get in touch with us. Simply fill in here and we will get back to you as soon as possible.

Best-Practice Solutions

In this video we show the latest developments and optimizations of our application heads using the TapeHead-3000 as an example.

In this video we show the application of single-sided tape with our NEW TapeHead-4000 and liner roll-up

In this video we show the possibilities of feasibility studies on the subject of apply with Cobot

In this video, we demonstrate the application of adhesive pads with a lightweight robot.

TH-2000 | In this video we show how to apply tape to vibration isolating material.

In this video we demonstrate plasma treatment for removing dirt and activating the surface.

TH 3000 | In this video, we demonstrate the robot-assisted application of double-sided adhesive tapes with liner rewind.

TH 2000 | In this video, we demonstrate applying of single-sided adhesive tapes and masking of parts e.g. to keep sensors and certain surfaces paint-free.

TH-1000 | In this video, we demonstrate applying of double-sided adhesive tapes.

PrimerPen-1000 | Interchangeable system: in this video, we show the robot-assisted application of primer for adhesion primer preparation using a Primer-Pen gripper.

Project in the automotive sector: robot-supported bonding application for body panels on the transmission tunnel (area where the gearshift lever is located).

Feasibility study in the automotive sector: robot-assisted application of double-sided adhesive foam rubber to e.g. plastic components.